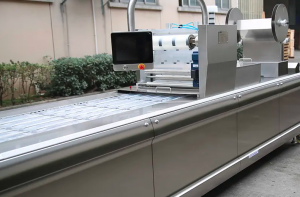

Mechini ea Pakete ea Pachufording ea PachuumBapala karolo ea bohlokoa indastering ea liphuthehong, e netefatsa hore lihlahisoa li sireletsehile 'me li tšoaisoa hantle ka mokhoa o hlakileng ho boloka bocha le ho holisa bophelo ba sehatse. Ho netefatsa ts'ebetso e telele le ea tlhoro ea mechini ena, tlhokomelo e nepahetseng ea bohlokoa. Sehloohong sena, re tšohla likeletso tse ling tsa bohlokoa tsa ho boloka mochini oa hau oa Pantel Inthaneteng.

1. Ho hloekisa khafetsa: Ho hloekisa kamehla ho bohlokoa ho thibela ho haha litšila, maloanlahla le lijo tse mabapi le likarolo tsa mochini. Latela litaelo tsa ho hloekisa moemeli, tse ka kenyelletsang ho sebelisa li-enternar kapa tharollo. Ela hloko ka ho khetheha libaka tse tsitsitseng le tse sehiloeng, joalo ka ha masala a libakeng tsena li tla ama boleng ba sephutheloana seo. Etsa bonnete ba ho hloekisa likarolo tsohle ka botlalo 'me u lumelle ho omella pele u sebelisa mochini hape.

2. Lubrication: Ho kopanya likarolo tse tsamaeang tsa mochini ho thusa ho fokotsa likhohlano le ho netefatsa ts'ebetso e boreleli. Lekola tataiso ea moetsi ho tseba hore na lubricant e loketseng le khafetsa ea lubrication. Ho itlotsa ka bophara ho hohela litšila le maloanlahla, ka hona, etsa bonnete ba ho sebelisa libricant ka mokhoa o hlakileng le ho hlakola tse ngata.

3. Hlahloba le ho khutlisa likarolo tse khabisitsoeng: Hlahloba mochini ka matšoao a ho roala joalo ka mapetso a joalo ka mapetso a maputsoa, lilithara tse khathatsang kapa li-screws tse ntle. Hang-hang sebaka se senyehileng kapa se kopuoa ho thibela tšenyo e 'ngoe ho mochini le ho boloka sephutheloana se le teng. Boloka likarolo tsa phomolo li le matsohong ho fokotsa nako ea phomolo le ho netefatsa tlhahiso e sa sebetseng.

4. Lekala mochini: Latela litaelo tsa moetsi ka ho hatisa mochini ka nepo. Ho leka-lekana ho ka kenyelletsa ho fetola maemo a iphetetsang, ho nka lintho tse futhumatsang, kapa ho nchafatsa linako.

5. Koetlisa basebetsi ba koetlisa: Ba sebetsang hantle ka nepo ho bohlokoa ho boloka le ho sebelisa metjeko ea PackoHivations e sebetsang. Etsa bonnete ba hore batsamaisi ba mechini ea mochini ba tseba tšebetso ea mochini, litataiso tsa polokeho le lits'ebeletso tsa tlhokomelo. Fana ka linako tsa koetliso khafetsa ho ntlafatsa tsebo ea bona le ho netefatsa hore li khona ho khetholla le ho rarolla litaba tse ka bang teng ka nako e nepahetseng.

6. Latela tataiso e khothalelitsoeng bakeng sa ts'ebeliso:Mechini ea Pakete ea Pachufording ea PachuumE-ba le tataiso e ikhethang bakeng sa ts'ebeliso e fanoang ke moetsi. Latela litataiso tsena ka hloko ho qoba ho imelisa mochini ebe u baka likotsi tse ngata. Se ke oa feta palo e khothalletsoang ea mekotla ka motsotso, kaha sena se ka hatisa mochine mme o khutsufatsa bophelo ba sona.

7. Boloka logong ea ho lokisa: Boloka lethathamo la tlhokomelo ho hatisa mesebetsi ea tlhokomelo, ho kenyelletsa ho hloekisa, lubrication le ho lekanya likarolo. Rekoto ena e ka thusa ho latela nalane ea mochini oa mochini 'me u khetholle litaba tse etsahalang khafetsa kapa mekhoa e thata. Hlahloba li-log khafetsa ho netefatsa hore mesebetsi ea tlhokomelo e ntse e tsoela pele joalo ka ha ho ne ho reriloe.

Qetellong, tokiso ea kamehla e bohlokoa bakeng sa ts'ebetso e nepahetseng le e telele ea mochini oa hau oa ho tsamaisa vachuum o phetseng hantle. Ka ho latela likeletso tsena tsa tlhokomelo, u ka boloka mochini oa hau o ntse o tsamaea hantle, o fokotsa nako ea nako ea ho phomola le ho hlahisa tšebeliso ea boleng bo phahameng haholo. Hopola ho buisana le tataiso ea moetsi bakeng sa litaelo tse ikhethang tsa tlhokomelo ea litokiso, 'me u lule u sireletsehile pele ha u sebelisa mechini ena.

Nako ea poso: Jun-29-2023